It's easy for us to get ahead of ourselves when talking about PDM systems. It's our second language, what we work with every day. That being said, if we want firms to give us a chance, it is imperative that they understand just what PDM does, and what the right strategy can do for them.

First, let's answer "what is PDM?" Product data management is a function responsible for the management and publication of product data. Product data management always exists. Even Henry Ford had a PDM system. It was certainly not a 3D CAD of a Model T. It consisted of clipboards, workers, and his paper blueprints. Ford did not even introduce an assembly line until 1913, 5 years after he began producing the Model T. The point is, Ford's PDM was the best there was in 1900. Is your firm still using systems from 1900?

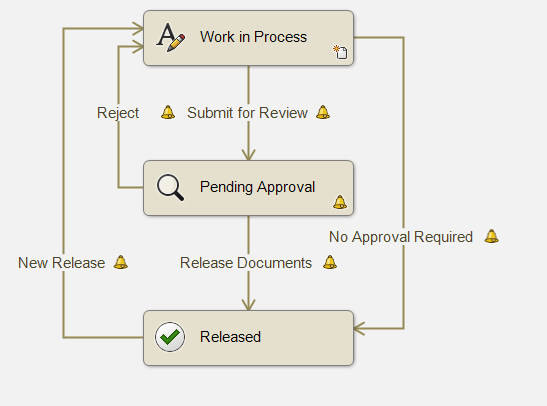

SOLIDWORKS Product Data Management (PDM) is a program that honestly makes life easier. It helps take you from blueprints to databases on your computer. SOLIDWORKS is a PDM strategy tool that is essentially a Windows add-on. It saves a full history of every design, so if you decide to keep an element you had previously removed, it's as simple as reopening a file. Not to sound dramatic, but it is the backbone of data management. The workflow is concise, clear, and easy for everyone to use.

Is product data management a source of stress for you?

One of the things we hear over and over is that manufacturers and engineers get in each other's way. Whether it be manufacturing producing a design that was not ready yet, or engineers and designers misplacing design iterations, data management strategy has been a struggle for years. With workflow features, only the right people have access to designs at the right time. By making processes more intentional, we remove much of the room for error. We want to not only give you the tools to seamlessly manage your production chain, but also help you transition from your existing system to SOLIDWORKS PDM.

But can you afford a new PDM strategy?

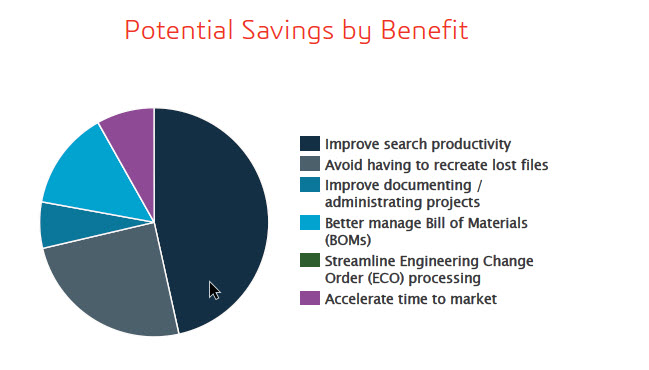

A common misconception is that a PDM system is too expensive to implement. While the leap can be daunting, a PDM system can save you money in a lot of ways. Data management on a shared drive is clunky and spending time recreating lost files is a waste of time. It's slow and ineffective. There is actually a tool that can be used to calculate how long it would take your specific firm to get a return on investment.

Using the PDM ROI calculator is a great step in explaining just how valuable a PDM system can be, with real numbers that are specific to your firm. This blog from Solidworks explains the tool more thoroughly, and even shows an example in which the firm is potentially saving over half a million dollars every year by implementing an updated PDM strategy. What could your firm do with an extra $500,000 every year?

We wholeheartedly believe that PDM is the way of the future. It gives an edge now, but soon if you don't have it, you'll be behind. We are here to help every step of the way, from transition to support. Contact us to learn more, we are available almost every day via Zoom meeting, email, or phone. Now more than ever, we know communication is key. We are still available for support, and let's be honest, with social distancing, we are excited to hear from you!

EQUIVAQ SOFTWARE offers Apps to enhance the lives of SOLIDWORKS PDM Administrators and users by offering advanced PDM Add-in Apps for an affordable monthly license fee in order to bring PDM automation within reach.

Our products are straight forward and come with detailed easy setup instructions to get you started.

EQUIVAQ SOFTWARE offers Apps to enhance the lives of SOLIDWORKS PDM Administrators and users by offering advanced PDM Add-in Apps for an affordable monthly license fee in order to bring PDM automation within reach.

Our products are straight forward and come with detailed easy setup instructions to get you started.